| About Bolt Products | Bolt Products Homepage | Bolting Information | Catalogue |

| Sustainable Bolting and Bolt Removal | Strength and Tests These are tests relating to Bolt Products bolts in various conditions and rock and are given as guidance and information for our customers. For more general information on bolt testing, test rigs, bolt strength calculation, design and other independent tests performed on a wide variety of bolts go to Bolting Information |

| Strength and Tests | |

| Bolt Selection | |

| Orders, Delivery and Discounts | |

| Protection Bolts | |

| Belay Bolts | |

| Sea Water Series | |

| Single Point Lower-offs | |

| Chain Extenders | |

| Chain Sets | |

| Stainless Steel Pitons | |

| Maillons, Rings and Chain | |

| Via Ferrata Equipment | |

| Glue and glue guns | |

| Accesories | |

| Service and support | |

| Terms and conditions |

Test Criteria and Terminology

For climbing purposes rock anchors (bolts) fall under the scope of EN959. This calls for a test strength in an axial direction of 15kN and in a radial direction of 25kN.

These tests are carried out in a standardised test block of specified concrete with a compressive strength of 50N/mm²

Axial testing is pulling outwards along the axis of the bolt (straight out).

Radial is pulling at 90° to the axis .

Introduction

Generally the axial test is the harder and we normally do most of our testing in this way. Our internal standards are higher than those of EN959 and the UIAA in that we require all our bolts to achieve over 25kN in all directions and so test axially first. The failure mode of most bolts tested radially is in fact a tensile failure, i.e. the same as if axially tested as the bolt tries to slide out of the hole, this is the case even with bolt-in bolts.

Test Rig

We use a 10 ton hydraulic cylinder with a two to one leverage to give a nominal 20 ton pull through a 10,000 kg rated Transducer Technology Inc load cell with a VMC electronic strain guage calibrated by the manufacturer to an accuracy of 2kg.

![]()

Glue-in Protection Bolts

Our twisted leg design combines both mechanical and chemical fixing making them much stronger than other bolts on the market. Here are some typical test results.

Test conditions. Dry (indoors). Air Temp 17°C. Rock and glue temp 17°C.

Rock. Coarse grained Granite.

Compressive strength. Over 200N/mm²

Adhesive. Polyester.

Cure time. 4 hours

Cleaning. All bolts cleaned with acetone. Holes brushed and blown out with compressed air at 8 bar.

Bolt Hole dia. Test Direction Failure strain Failure Mode

Bolt Products 6mm rod. 80mm long 12mm Axial 49,22kN Bolt broke at eye.

Bolt Products 6mm rod. 100mm long 12mm Axial 50,16kN Bolt broke at eye

Bolt Products 8mm rod. 80mm long 16mm Axial 47,63kN Test block failed

Bolt Products 6mm x 80mm bolt failure at 49,22kN with still no movement of the bolt itself.

![]()

Dry tests

To demonstrate the additional mechanical fixing of Bolt Products bolts we test them dry (without glue).

Test conditions.Indoors. Air Temp 17°C. Rock and glue temp 17°C.

Rock. Coarse grained Granite.

Compressive strength. Over 200N/mm²

Adhesive.None

Cure time.-

Cleaning. Holes brushed and blown out.

Direction of test. Axial and radial.

Bolt Hole dia. Test Direction Failure strain Failure Mode

Bolt Products 6mm rod. 80mm long 12mm Axial 12,35kN Bolt pulled out

Bolt Products 6mm rod. 80mm long 12mm Radial 20,01kN Bolt pulled out

Bolt Products 6mm rod. 100mm long 12mm Radial 21,17kN Bolt pulled out

Bolt Products 6mm rod. 150mm long 12mm Radial 22,59kN Bolt pulled out

Bolt Products 8mm rod. 150mm long 16mm Radial 26,46kN Test block failed

6mm x 80mm bolts after dry axial testing (left) and radial (right)

We then moved to a concrete test block

Test conditions.Outdoors. Air Temp 13°C. Concrete temp 11°C.

Rock. Concrete

Compressive strength. 30N/mm²

Adhesive.None

Cure time.-

Cleaning. Holes brushed and blown out.

Direction of test. Axial and radial.

Bolt Hole dia. Test Direction Failure strain Failure Mode

Bolt Products 6mm rod. 80mm long 12mm Axial 8,3N Bolt pulled out

Bolt Products 6mm rod. 80mm long 12mm Radial 15,22kN Bolt pulled out

Bolt Products 6mm rod. 100mm long 12mm Radial 18,13kN Bolt pulled out

Bolt Products 8mm rod. 150mm long 16mm Radial 34,19kN Bolt pulled out

6mm x 80mm (top right) 8mm x 150mm (centre) and 6mm x 100mm (lower left) after dry radial testing in concrete.

![]()

Limestone test.

Here is a test series we performed in the northern Frankenjura. Germany.

Test conditions.Outdoors. Damp. Air Temp 7 °C. Rock temp 5 °C. Glue temp 7°C.

Rock. Jura Limestone

Compressive strength. 40N/mm²

Adhesive.Polyester

Cure time.16hours

Cleaning. Holes brushed and blown out. (rock extremely damp and hard to clean)

Direction of test. Axial and radial.

Bolt Hole dia. Test Direction Failure strain Failure Mode

Bolt Products 6mm rod. 80mm long 12mm Axial 36,75N Glue/rock interface failed

Bolt Products 6mm rod. 100mm long 12mm Axial 41,75kN Glue/rock interface failed

Bolt Products 6mm rod. 100mm long 12mm Radial 45,68kN Tester anchor failed, bolt intact

Bolt Products 8mm rod. 80mm long 16mm Axial 34,19kN Glue/rock interface failed

Bolt Products 8mm rod. 100mm long 16mm Axial 37,24kN Glue/rock interface failed

Bolt Products Monster Bolt 130mm long 16mm Axial 57,43kN Glue/rock interface failed

(The radial test anchor which failed was a M16 x 150mm Fischer steel wedge bolt and I had no replacement)

![]()

Sandstone Test

These tests were independantly carried out in the U.S.A. to asses the suitability of Bolt Products bolts for use in extremely soft sandstone.

They were so succesful that Bolt Products bolts were chosen for bolting new areas and re-bolting existing routes.

Test conditions.Outdoors. Unknown

Rock. Corbin Sandstone

Compressive strength. Laboratory tested at 7,14N/mm²

Adhesive.Hilti Hit RE500 Epoxy

Cure time.50hours

Cleaning. Not stated.

Direction of test. Radial.

Bolt Hole dia. Test Direction Test Load Failure Mode

Bolt Products 6mm rod. 150mm long 1/2" Radial 25+kN No Failure

Quote:-

"This is only the second time we have tested a bolt or bolted hanger bracket to the maximum force specified by UIAA and it has not been destroyed in the process. the Fixe 5-inch glue-in held at 25 kiloNewtons, but with a little more force the weld broke. Remember also that bolted hanger brackets with Rawl-type Powers bolts and Dynabolt Golds blew their heads around 4500 pounds."

![]()

Cyclic Loading Tests

And then, to simulate repeated falls;-

Test conditions.Outdoors. Unknown

Rock. Corbin Sandstone

Compressive strength. Laboratory tested at 7,14N/mm²

Adhesive.Hilti Hit RE500 Epoxy

Cure time.Not stated

Cleaning. Not stated.

Direction of test. Radial.

Test Protocol: Bolt a) 6 x 150mm bolt deliberately installed with 12mm of the shaft exposed. Static load of 2,23kN. Load increased in less than 0,3 sec to 5,4kN. Repeated 100 times. Then test loaded to 25kN..

Bolt b) 6 x 80mm bolt correctly installed. Same repeat test as above. Test loading stopped at 31,4kN.

Bolt Hole dia. Test Direction Test Load Failure Mode

Bolt a) Bolt Products 6mm rod. 150mm long 1/2" Radial 25kN No Failure, bolt still in place.

Bolt b) Bolt Products 6mm rod. 80mm long 1/2" Radial 31,4kN No Failure, bolt still in place.

Quote:-

"The tests were an overwhelming success."

![]()

Simulated lead falls- we felt a higher test load was required and so:-

Test conditions. Dry (indoors). Air Temp 13°C. Rock and glue temp 13°C.

Rock. Coarse grained Granite.

Compressive strength. Over 200N/mm²

Adhesive. Polyester.

Cure time. 11/2 hours

Cleaning. Holes blown out with pump, brushed and blown out.

Protocol:- Fast load (under 0,2 sec.)/unload cycle.

Bolt Hole dia. Test Direction Test Load No of cycles Failure Mode

Bolt Products 6mm rod. 80mm long 12mm Axial 0kN-25kN 1000 No Failure, bolt still in place.

0kN-30kN 100 No Failure, bolt still in place.

0kN-35kN 100 No Failure, bolt still in place.

0kN-40kN 100 No Failure, bolt still in place.

0kN-44,8kN Rock edge failure

(this test block had a number of other test holes drilled in it and the bolt was less than 50mm from the edge)

After block failure.

![]()

Simulated lead falls- bolt-in.

Test conditions. Dry (indoors). Air Temp 13°C. Rock and glue temp 13°C.

Rock. Coarse grained Granite.

Compressive strength. Over 200N/mm²

Adhesive.-

Cure time. -

Cleaning. Holes blown out with pump.

Bolt Hanger. Bolt Products 6mm rod belay hanger.

Protocol:- Fast load (under 0,2 sec.)/unload cycle.

Bolt Hole dia. Test Direction Test Load No of cycles Failure Mode

MKT M10 Bolt-in .60mm embedment 12mm Axial 0kN-25kN 172 Rock edge failure

(this bolt was in the same block as above and also near an edge.)

We will repeat this test soon in an undamaged block to achieve bolt failure.

![]()

Lower Offs

Bolt Products Monster Hook

Test conditions. Dry (indoors). Air Temp 17°C. Rock and glue temp 17°C.

Rock. Coarse grained Granite.

Compressive strength. Over 200N/mm²

Adhesive. Polyester.

Cure time. 2 hours

Cleaning. Holes brushed and blown out with compressed air at 8 bar.

Test performed using hardened 14mm pin to replace rope.

Bolt Hole dia. Test Direction Failure strain Failure Mode

Bolt Products Monster Hook 12mm x 130mm 12mm Radial 58,43N Eye Failure (rope release). No bolt movement.

Above. At 2880kN the eye starts to deform

Point of failure, the end of the "knot" is about to pull through-58,43kN

![]()

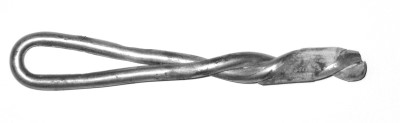

Pigtails

Test conditions.Indoors. Air Temp 17°C.

Rock. -

Compressive strength. -

Adhesive.-

Cure time.-

Cleaning. -

Direction of test. Radial.

Bolted to test rig.

Test performed using 12mm hardened bolt to replace rope.

Bolt Hole dia. Test Direction Failure strain Failure Mode

Bolt Products 10mm rod Pigtail Radial 15,6kN Bent open to rope release point

Bolt Products 12mm rod Pigtail Radial 35,80kN Bent open to rope release point

This is a 12mm pigtail at the point at which the force required to bend open starts to decrease, in this case 35,8kN.

![]()

Rings

We make all our own rings and batch proof test them to 50kN. Destruction testing is difficult as our current test rig is limited to 10,000 kg and is unable to measure the force required to break the10mm and 12mm rings.

Test conditions.Indoors. Air Temp 17°C.

Rock. -

Compressive strength. -

Adhesive.-

Cure time.-

Cleaning. -

Direction of test. Tension

Bolted to test rig.

Test performed using 14mm and 16mm pin.

Bolt Test Direction Failure strain Failure Mode

Bolt Products 8mm rod welded ring Tension 54,9kN Tester Pin failed

Bolt Products 8mm rod welded ring Tension 72,96kN Ring failed beside weld

![]()

Bolt Hangers

A test of Bolt Products welded rod hangers.

Test conditions.Indoors. Air Temp 17°C.

Rock. -

Compressive strength. -

Adhesive.-

Cure time.-

Cleaning. -

Direction of test. Radial.

Bolted to test rig.

Bolt Test Direction Failure strain Failure Mode

Bolt Products 6mm rod hanger, 10mm bolt Radial Average of 10 hangers 32.8kN Hanger failed.

Lowest 31.4kN

Highest 34.3kN

Bolt Products 8mm rod hanger, 12mm bolt Radial Average of 10 hangers 58.3kN Hanger failed

Lowest 54.2kN

Highest 59.1kN

![]()

Miscellaneous

Hole cleaning

This was a test done to illustrate the need for good hole cleaning for glue-in bolts, bolt-ins are not so critical but still should be reasonably clean.

Test conditions.Outdoors. Air Temp 18°C. Concrete temp 16°C.

Rock. Concrete

Compressive strength. 30N/mm²

Adhesive.Polyester

Cure time.-24hrs

Cleaning. Holes brushed and blown out to various standards.

Test.Three identical bolts were glued into

a) hole blown out but not brushed.

b) hole blown out with 8bar compressed air.

c) hole blown, brushed and blown again (normal practice)

Bolt Hole Test Direction Failure strain Failure Mode

Bolt Products 6mm rod. 80mm long a) Axial 10,4kN Glue/concrete interface failed

Bolt Products 6mm rod. 80mm long b) Axial 15,3kN Glue/concrete interface failed

Bolt Products 6mm rod. 80mm long c) Axial 34,7kN Glue/concrete interface failed

Top;- typically poor adhesion with an unbrushed hole, glue pulls out as a plug.

Centre;- the glue held a bit better as one can see in the middle of the bolt where the glue has crumbled under load but the cleaning effect of the compressed air was limited lower in the hole.

Bottom;- the glue has bonded well to the concrete and is then crushed and falls apart under pressure.

![]()

Studs

I have been using these for some years and have tested them the hard way by falling off but here are some test results, all radial tested as I wouldn´t use them for axial loading!

Bolt Rock Test Direction Failure strain Failure Mode

Bolt Products 6mm rod stud. 6mm x 25mm long Granite Radial 13,8kN Stud pulled out

Bolt Products 6mm rod stud. 6mm x 25mm long Soft Limestone Radial 6,2kN Stud pulled out

Bolt Products 6mm rod stud. 6mm x 25mm long Hard Limestone Radial 8,3kN Stud pulled out

![]()